Piling in Africa? Here's what you need

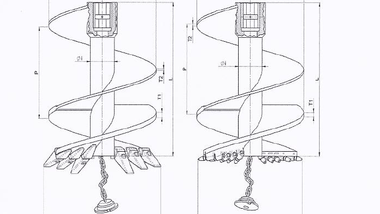

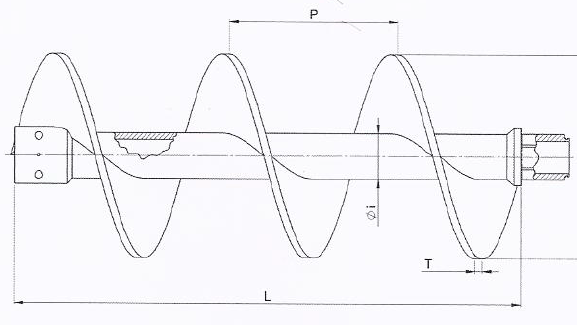

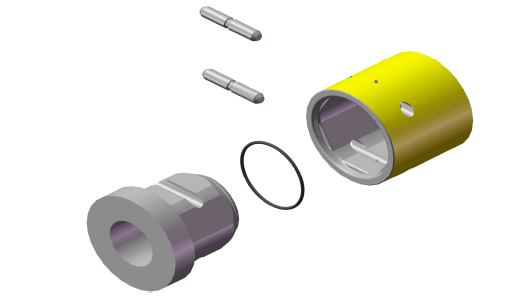

As shown below, these augers use male and female couplings. Furthermore, these augers have other tooling like Blow off Caps/Bungs, Rock Teeth/Bullet Teeth and Holders, Soil Teeth and Holders. All of which are supplied by Pilequip.

The big question is which rig uses the CFA auger? That is where Soilmec comes in.

Soilmec can be configured in either CFA or Kelly mode. This all depends on what application is to be used by the contractor. Soilmec is a durable brand recognised all over the world.

When the client is required to do CFA piles, the CFA auger

is attached to the Soilmec rig. A CFA clay or Rock Auger head is attached at the end using the male and female couplings. When drilling, wear occurs on the Teeth, Holders and Blow off Caps/Bungs (replaced in every pile). Which Pilequip supplies.

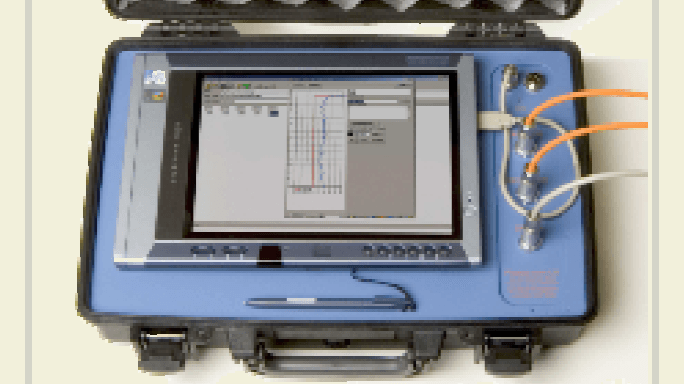

As Soilmec rigs are sophisticated they requires special measurement and control technology. This can be achieved through one of the various Jean Lutz technological systems.

Jean Lutz specialises in the design, manufacture and implementation of special measurement and control devises for monitoring ground improvement techniques on major works worldwide, including deep foundation and geotechnical instrumentation used in the construction of dams, tunnels, subways and roads.

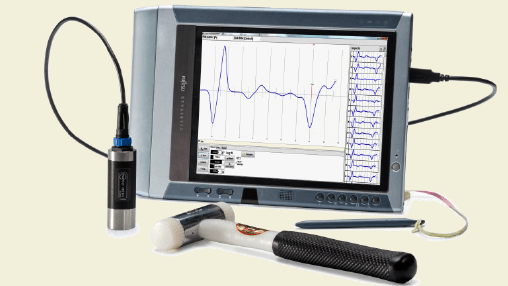

As seen below, once Piling is complete the next step is to test your piles. Piletest offers devices in different ranges such as the Piletest PET (Pile Echo Tester) either in Bluetooth or USB and Piletest CHUM (Cross Hole Ultrasonic Monitor) to accurately and efficiently test your piles.

The most commonly used, flexible and user-friendly device is the Piletest’s Pile Echo Tester (PET) as it tests a large number of deep foundations quickly and accurately. Requiring little-to-no training, PET is a modular, computer-independent system that attaches to the USB port of any regular Notebook, Tablet PC and Android mobile.

The PET system utilizes the pulse-echo method (compliant to the ASTM D

5882-16 & AFNOR P160-2,4 standards). To test a pile, the user strikes it with PET’s lightweight handheld hammer and then the resulting signal, or reflectogram, is captured by PET’s digital accelerometer. Lastly it is transmitted to the computer to produce information about the pile’s length and shape.

Should you require a more complex method, the CHUM is for you.

The CHUM uses the Cross-Hole Sonic Logging (CSL) method to perform high-resolution quality assurance on deep foundations. An ultrasonic wave is sent from a transmitter to a receiver pulled through the whole length of the pile in access tubes embedded before casting. The measured wave velocity and energy are strongly dependent on the concrete quality. Additional methods supported by the CHUM are Single Hole Ultrasonic Testing (SHUT) and Tomography (two- and three-dimensional).

In the case where building boreholes, Pilequip also supplies the Piletest BIT (Borehole Inclination Tester).

All piling specifications prescribe the allowable deviation of the pile axis from the vertical and unlike traditional systems, BIT uses the Auger/Bucket itself as a centralizer, thus eliminating the need for a bulky system. The BIT enables fast and accurate determination of inclination in both dry and wet boreholes, vertical or raked.

Large boreholes and diaphragm-walls may be quickly tested several times during drilling to enable real-time corrective action. Finished pile inclination can be measured through the CSL access tubes.

These are a few of the long standing partnerships we have and offer to our Pilequip clients. We are confident in our products and in our relationships to get the job done.

You might also like